Canik Mete & TTI Combat to RMR (Holosun 407C, 507C, 507 COMP, 508T) Aluminum Plate - DPP

$40.00Unit price /UnavailableCZ Shadow 2 Compact to Holosun 407/507K/EPS Carry - Calculated Kinetics

$64.99Unit price /UnavailableCZ P10 to RMR/SRO Holosun 407C/507C/508T - CHPWS - CPCZ-RSH

$89.97Unit price /UnavailableIn stock (74 units)S&W M&P 2.0 Full Size/Compact to K Footprint Adapter Plate 407K/507K/EPS Carry/EPS - Aluminum - DPP

$39.99Unit price /UnavailableSpringfield Hellcat OSP/RDP/PRO to Holosun 407K/507K/EPS Carry Adapter Plate - CHPWS - SAHC-HOLOk

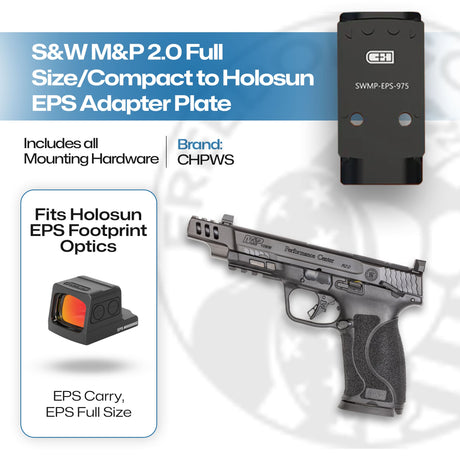

$64.99Unit price /UnavailableIn stock (71 units)S&W M&P 2.0 to Holosun EPS/EPS Carry - Aluminum - CHPWS - SWMP-EPS-975

$64.99Unit price /UnavailableIn stock (41 units)FN 509/510/545 to RMR Holosun 407C/507C/508C Adapter Plate - CHPWS - FN509-RSH

$86.95Unit price /UnavailableIn stock (24 units)Glock 43X/48 MOS to Holosun EPS Carry Adapter Plate - Aluminum - DPP

$39.99Unit price /UnavailableCZ P10 to RMR (Holosun 407C, 507C, 507 COMP, 508T) Titanium Plate - DPP

$50.00Unit price /Unavailable- $39.99Unit price /Unavailable

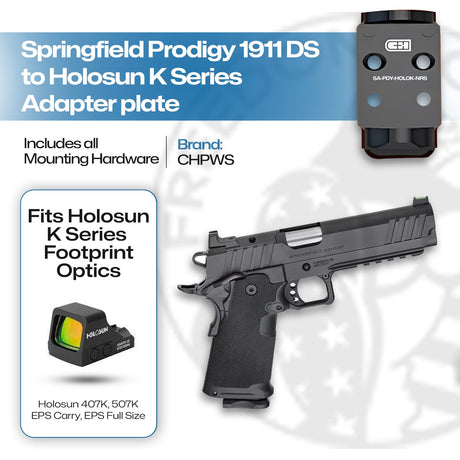

CHPWS SA PRODIGY ADPT HOLO 407K/507K - AOS-HOLOK-NRS (No Integrated Rear Sight)

$86.95Unit price /UnavailableIn stock (28 units)- $70.45Unit price /UnavailableLow stock (15 units)

Glock 43x/48 MOS to Holosun 407K/507K Adapter Plate - CHPWS - GLX-HOLOk

$64.99Unit price /UnavailableIn stock (552 units)

Quality Adapter Plates for Optic Fitment

These engineered adapter plates create the foundation needed for reliable red dot performance. Unlike universal mounting solutions that compromise on fit and stability, these model-specific plates are designed using dimensional specifications for your firearm and optic. This matching provides alignment, correct screw depth, and suitable mounting height for your shooting needs.

Each adapter plate is made from durable materials like aircraft-grade aluminum or titanium, providing strength while minimizing added weight. The machining process creates threading that matches factory specifications for your firearm and optic, preventing stripping issues and creating secure attachment through regular use.

Firearm and Optic Compatibility

Our adapter plate collection covers popular combinations of optics-ready pistols and red dot sights:

- Glock MOS - For full-size, compact and slim models with factory optic cuts

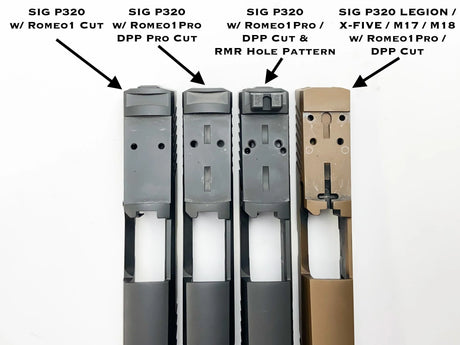

- Sig Sauer - P320 series, P226/P229, and P365 with Romeo cuts or standard dovetails

- Smith & Wesson - M&P 2.0, Shield Plus, Shield EZ, and competition models

- Springfield - Hellcat OSP, XD series, 1911 EMP, and Prodigy models

- CZ - P-10, Shadow 2, and P-01 platforms with optic cuts

- Canik - METE, TP9 Elite, SFX, and SFT models with various factory cuts

- FN - 509, 510, and 545 with MRD optic cuts

- HK - VP9 with OR slide and standard models

- Walther - PDP, PDP-F, and Q5 Match models

- Arex Delta Gen 2 - For models with factory optic cuts

Our collection includes mounting solutions for major red dot footprints including RMR, K Series (modified RMSc), DPP/DRS, 509T, ACRO, and specialized mounts for unique optics and firearm combinations.

DOGTAG Adapter Technology from Calculated Kinetics

The Calculated Kinetics DOGTAG adapter plates use a patented design that distributes recoil forces across the entire mounting surface rather than relying solely on the mounting screws. This design helps prevent screws from loosening or breaking during extended use.

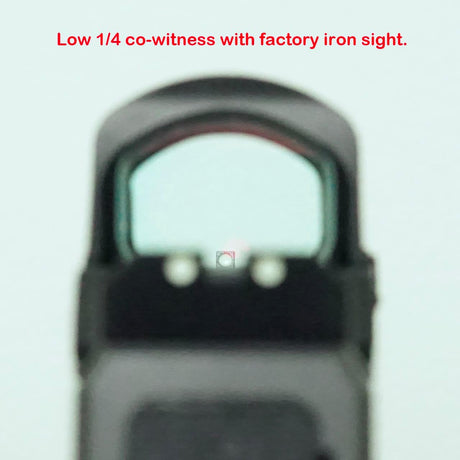

The DOGTAG system also provides height matching between your iron sights and red dot, creating a transition between sighting systems. This alignment is useful for training and creates a natural sight picture for target acquisition.

Material Options and Design Features

Adapter plates in our collection feature several material and design options: Aircraft-grade aluminum provides a balance of weight, strength, and affordability for most applications. This material is machined to tight tolerances and often features a protective anodized finish that prevents corrosion and maintains appearance. Titanium adapter plates offer a strong strength-to-weight ratio for durability in harsh conditions. These options work well for duty use, competition, and applications where reliability is important.

Many plates include features like rear sight integration, sealing plates for water resistance, or specialized mounting posts for specific optic types. These additions help your mounting solution address different aspects of optic installation.

Installation Process and Hardware

Installing your adapter plate properly helps performance and reliability. Most installations require basic tools, including the appropriate Torx bit for your specific optic, a blue thread locker, and in some cases, a torque wrench for proper screw tension.

The installation process typically involves preparing the slide by removing any existing plates, cleaning the mounting surface, applying thread locker to the screws, positioning the plate correctly, and tightening to the recommended torque specification. This process creates a secure foundation that reduces shifting during recoil and helps maintain your zero.

All adapter plates include the appropriate mounting hardware with the correct thread pitch and length for your specific application. Using these provided screws is important, as incorrect hardware can damage both your optic and firearm or create an insecure mounting solution.

Choosing the Right Adapter Plate

Selecting the correct adapter plate requires matching your firearm model and optic footprint. The "footprint" refers to the pattern of mounting holes and registration features on the bottom of your red dot sight. Common footprints include:

- RMR/SRO Footprint: Used by Trijicon RMR, SRO, Holosun 407C/507C/508T

- K Series Footprint: Used by Holosun 407K/507K/EPS Carry

- DPP Footprint: Used by Leupold DeltaPoint Pro and similar optics

- ACRO Footprint: Used by Aimpoint ACRO and similar enclosed emitter sights

- 509T Footprint: Used by Holosun 509T closed emitter optics

Our product descriptions indicate which firearm models and optic types each plate accommodates, helping with your selection process. When in doubt, contact our customer service team for guidance on selecting the adapter plate for your setup.

Browse our collection of adapter plates at Freedom Gorilla and find the mounting solution for your specific firearm and optic combination.